Thermal oil gypsum calcining production line

Thermal oil gypsum calcining production line is used to calcine desulfurized gypsum in power plants or phosphogypsum in fertilizer plants to obtain plaster of paris, which can be used as building materials to produce gypsum mortar, gypsum board, etc. The production line mainly includes the following equipment:

Thermal oil furnace, flash dryer, calciner, cooler, ball mill and related dust collector, bucket elevator, draught draft fan and Roots blower, etc.

The capacity is 100,000~500,000 ton per year.

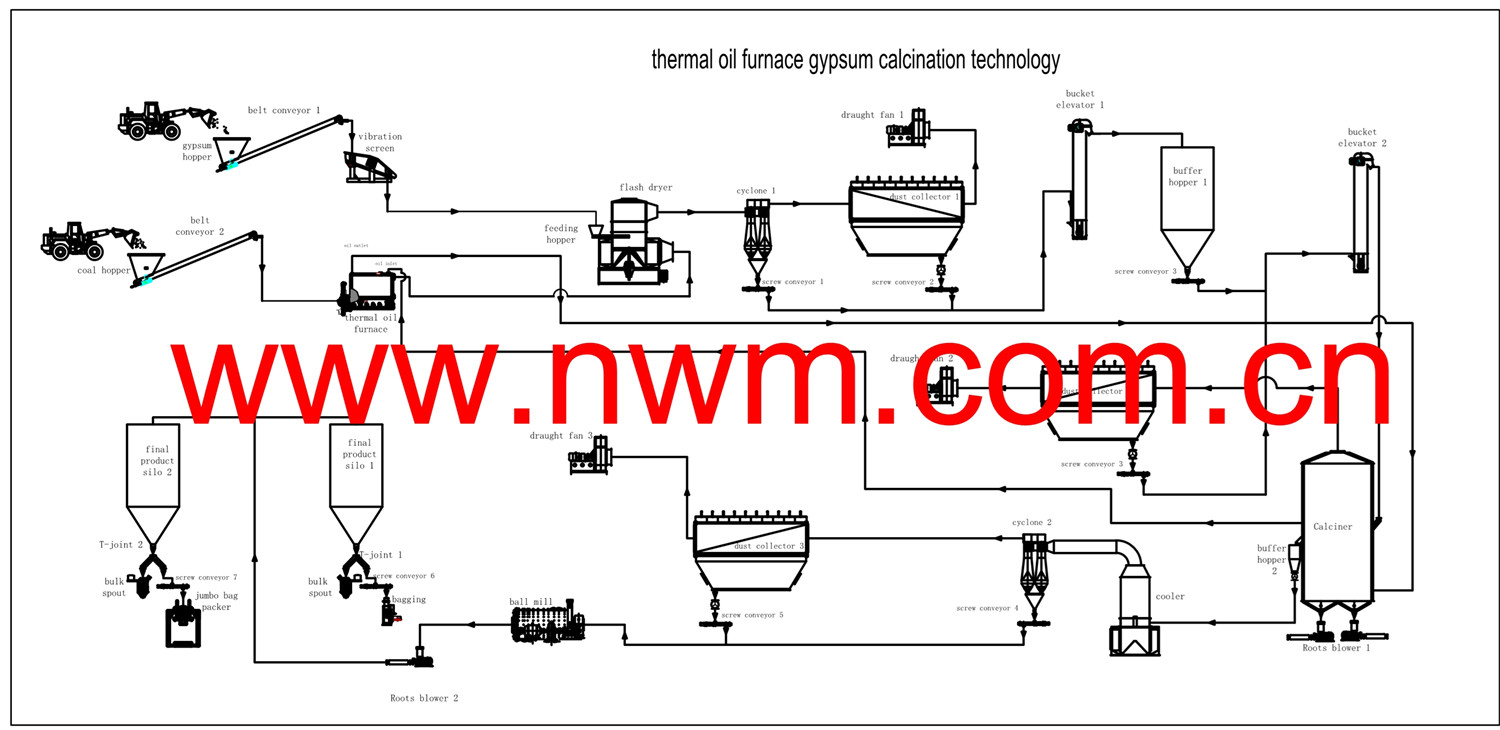

The technology flow chart is as follow:

working principle:

The raw materials are screened and then enter the flash dryer to remove the surface moisture, then lifted to the buffer tank for storage, and then entered into the ebullition furnace for calcination. , the calcined plaster of paris is ground by a ball mill, and then lifted into the finished product tank, and then packed in bulk or bags. By controlling the feeding amount and the temperature of the heat transfer oil, the temperature of the discharge port of the ebullition furnace is controlled.

Main equipment introduction:

Thermal oil furnace

The thermal oil furnace can use oil, natural gas, coal and biomass as fuel. The calcination heat source medium is thermal oil or steam. After the boiler flue gas is settled, it enters the flash dryer and contact with the material to dry the material, and the dried material passes through the cyclone dust collector and the bag filter and enters the buffer tank.

Flash dryer

After being heated, the air enters the main flash tower tangentially from the air inlet at the bottom of the main unit, forming a high-speed rotating airflow in the main tower. The material directly enters the drying tower through the screw feeder. Under the impact and drive of high-speed airflow, it disperses rapidly and rotates at high speed with the airflow; for relatively large and humid particles, the high-speed airflow is not enough to crush them and rotate at high speed, so they gradually fall under the action of gravity, and when they fall to the bottom of chamber, at the same time, it is forcibly crushed and atomized by the crushing device set at the bottom, and then rotates and rises with the airflow to complete the drying process. A classifier is set at the top of the main tower, and the final moisture and fineness of the discharged material can be controlled by adjusting the classifier and the air inlet speed.

Calciner (Ebullition furnace) Work principle:

The calciner is ebullition furnace, during normal operation, air is blown from the bottom of the ebullition furnace and enters the fluidized bed through the gas distribution plate. Bubbling air to make the bed fluidized, the heating pipe in the fluidized bed transfers a lot of heat to the material, so that the dihydrate gypsum powder reaches the temperature of dehydration and decomposition, and the dihydrate gypsum is dehydrated in the fluidized bed. And into steam, the steam is mixed with the air blown from the bottom of the furnace and moves upward through the bed. Due to the intense tumbling and mixing of the powder in the fluidized bed, the temperature and composition of the material are almost the same everywhere in the entire fluidized bed. The continuously input gypsum powder is mixed with a large amount of hot powder in the bed almost instantaneously as soon as it enters the bed, and is rapidly dehydrated and decomposed in the hot powder. The raw gypsum powder first enters the large box of the ebullition furnace to remove most of the crystal water, and then enters the small box of the ebullition furnace through the lower channel for dehydration, where the final dehydration process is completed, and then automatically overflows out of the furnace from the upper part of the bed.

The ebullition furnace medium is divided into three types: thermal oil, steam and hot air.

The effective heat exchange area is large and the operation control is accurate, thus retaining the advantages of frying pan calcination, and at the same time, the heat carried by steam or heat medium oil can be easily recovered and recycled.

Since there is no mechanical stirring device and the use of inner tube heat exchange, the maintenance work of the equipment is simplified, thus prolonging the service life of the equipment.

The character of system:

1. The whole set of production is designed to be operated by industrial computer, equipped with production data printing and real-time display of running thermometer. The control system adopts Siemens PLC and Advantech industrial computer. All material levels, on-off valves, material and mechanical operation, faults and solutions are monitored on-site in real time, and are dynamically displayed on the man-machine interface.

2. The entire production line has no pollution emission during the production process, and no dust falls on the ground. The connection part is sealed, and the part is soft connection. All dust emission locations are equipped with dust removal devices.